Enhancing Business Success Through Rapid Prototyping Services

In today's fast-paced industrial landscape, rapid prototyping services are becoming a cornerstone for businesses aiming to stay competitive. By providing a streamlined way to create prototypes, these services not only accelerate product development but also reduce costs and improve overall quality. Companies across various sectors, including metal fabricators, are increasingly leveraging these services to optimize their operations and enhance their customer offerings. In this article, we will explore the myriad benefits of rapid prototyping services and how they can drive success for your business.

What is Rapid Prototyping?

Rapid prototyping refers to the quick assembly of a scale model or the actual product using computer-aided design (CAD) software. In its essence, it allows designers and engineers to visualize and test their ideas quickly before moving into full-scale production. The different methods for rapid prototyping can include:

- 3D Printing: Allows for creating complex shapes using additive manufacturing techniques.

- CNC Machining: Involves cutting and shaping materials to create precise prototypes.

- Stereolithography (SLA): A technique using a laser to cure liquid resin into solid shapes, providing high detail and accuracy.

- Selective Laser Sintering (SLS): Utilizes a laser to fuse powdered material into solid structures.

Each method offers unique advantages that can be tailored to various applications within the metal fabrication sector and beyond.

The Importance of Rapid Prototyping in Business

Incorporating rapid prototyping services into your business model offers numerous advantages that can significantly impact your product development and market responsiveness:

1. Accelerating the Development Cycle

Time is of the essence in any competitive market. Rapid prototyping significantly shortens the product development cycle. Instead of waiting months for traditional prototypes, companies can produce and refine prototypes in days, if not hours. This agility allows businesses to get products to market faster, ultimately capturing consumer demand before competitors.

2. Cost-Effective Solutions

While the initial investment in rapid prototyping services might seem daunting, the long-term savings can be substantial. By detecting potential design flaws early in the process, companies can avoid costly reworks and modifications during full-scale production. Rapid prototyping also allows for efficient use of materials, minimizing waste.

3. Improved Quality and Performance

Rapid prototyping allows for iterative testing. Products can be continuously refined based on feedback gathered during testing phases. This leads to higher-quality final products that meet or exceed consumer expectations.

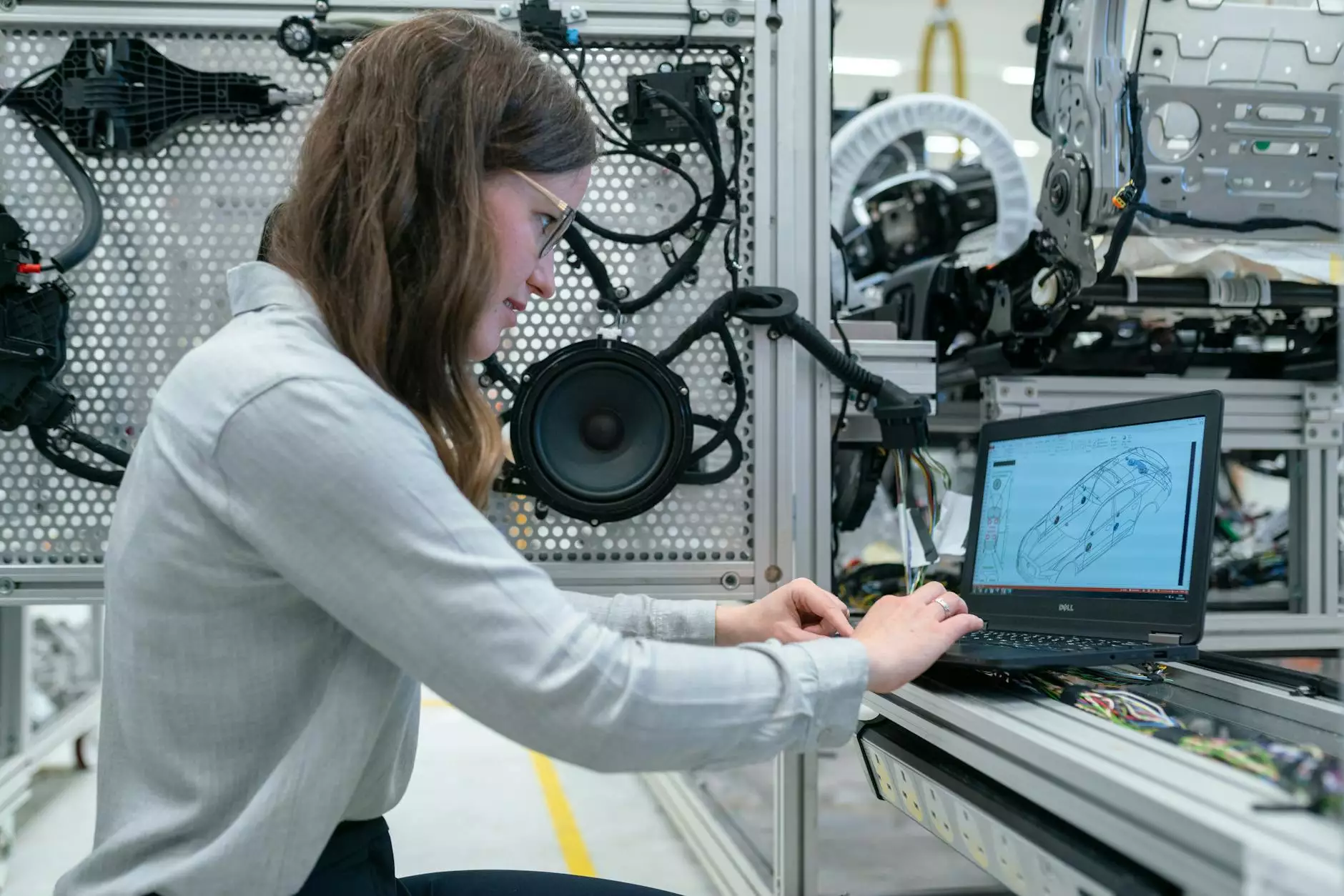

4. Enhanced Collaboration and Communication

Rapid prototyping services facilitate better communication between teams. Designers, engineers, and stakeholders can engage in discussions about tangible, physical prototypes rather than relying solely on visual representations. This collaboration helps ensure that everyone's vision is aligned, resulting in a more cohesive final product.

5. Greater Innovation

With the ability to quickly test and modify concepts, teams are encouraged to experiment. This leads to a culture of innovation where new ideas can flourish. Businesses that embrace rapid prototyping are often at the forefront of their industries, introducing groundbreaking products that resonate with customers.

Applications of Rapid Prototyping in Metal Fabrication

The metal fabrication industry particularly benefits from rapid prototyping services. Here are several applications where these services play a vital role:

1. Tooling and Fixture Development

Creating tools and fixtures can be resource-intensive and time-consuming. With rapid prototyping, manufacturers can produce functional tooling designs quickly, enabling faster production rates and enhanced operational flexibility. This ensures that metal fabrication processes remain efficient and cost-effective.

2. Custom Component Testing

Businesses often require custom parts for specific applications. Rapid prototyping enables immediate testing and validation of these components, ensuring they meet necessary specifications before full-scale manufacturing begins. This reduces the risk of failure and enhances overall product reliability.

3. Design Verification and Optimization

Before committing to large production runs, companies can use rapid prototyping to verify design integrity. By testing prototypes, they can identify and rectify potential issues early, ensuring the final product is optimized for performance, functionality, and user experience.