Crankshaft Manufacturers in China: A Comprehensive Guide

In the dynamic world of automotive manufacturing, crankshaft manufacturers in China play a crucial role. They are integral to the production of diesel engine parts and provide important innovations that drive the industry forward. This article delves into the intricacies of crankshaft manufacturing in China, providing insights into the processes, quality control, and reasons why many businesses opt for these manufacturers.

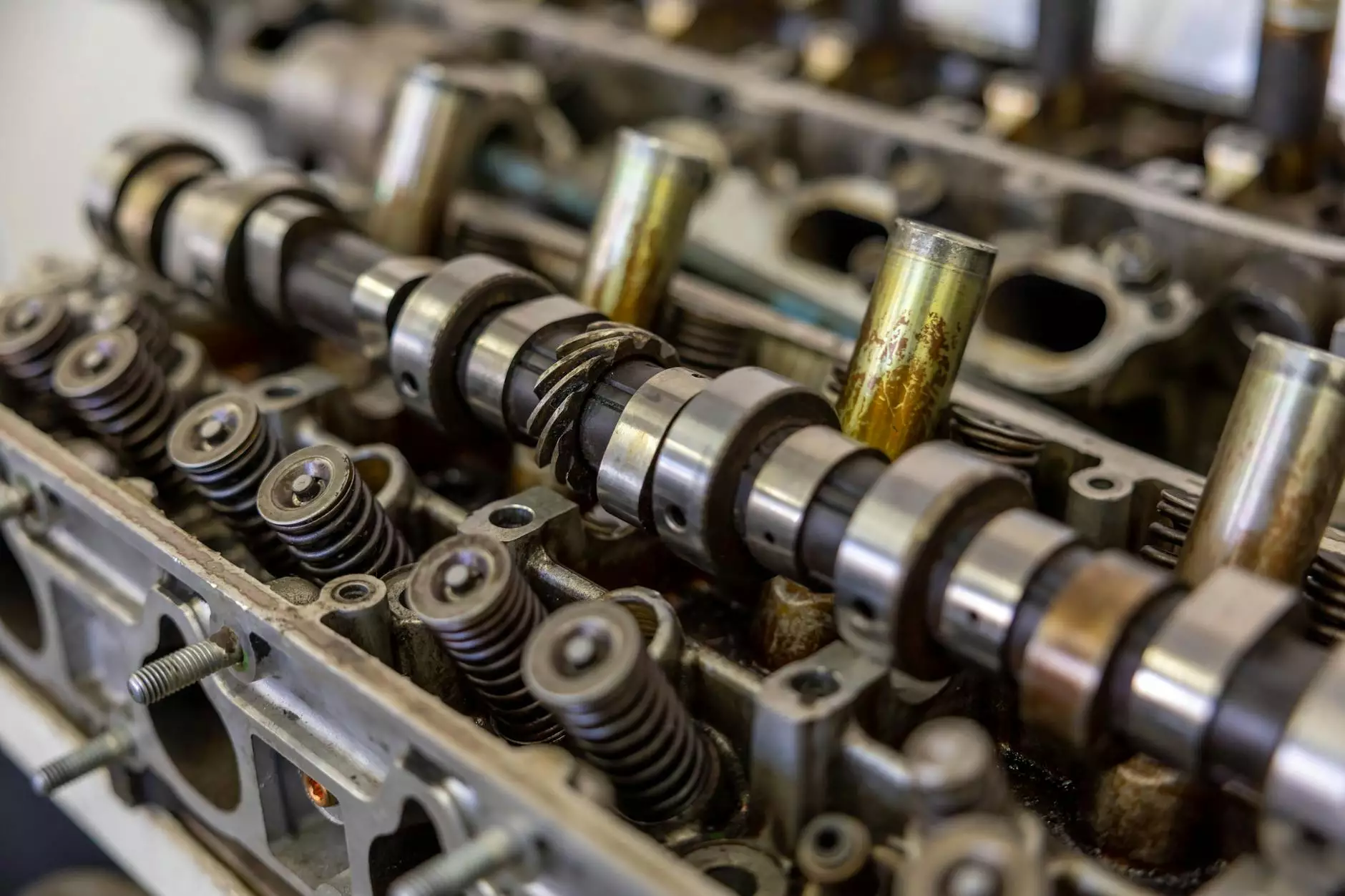

Understanding Crankshafts and Their Importance

The crankshaft is a vital component in any internal combustion engine. It converts the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. The quality of a crankshaft can significantly affect engine performance, efficiency, and durability.

For diesel engines, which are characterized by their robustness and efficiency, the crankshaft must withstand high stresses and extreme conditions. This is where the expertise of crankshaft manufacturers comes into play.

The Landscape of Crankshaft Manufacturing in China

China has emerged as a global leader in the manufacturing of crankshafts. The country is home to numerous companies that specialize in producing high-quality crankshafts for various applications, including automotive, marine, and industrial engines.

Quality Standards and Certifications

Chinese manufacturers adhere to international quality standards such as ISO 9001 and TS 16949. These certifications ensure that the crankshafts produced are of superior quality and meet the rigorous demands of clients worldwide.

Advanced Manufacturing Techniques

Many crankshaft manufacturers in China employ advanced manufacturing techniques, including:

- Precision Casting: This method allows for accurate and efficient production of complex shapes.

- Forging: Enhances the strength of the crankshaft, ensuring it can withstand high stress and fatigue.

- CNC Machining: Offers precision in the finishing processes, ensuring all specifications are met.

Top Suppliers and Their Offerings

When considering spare parts suppliers for crankshafts, it is essential to evaluate their product offerings, reputation, and customer service. Below are some of the top crankshaft manufacturers in China:

1. Jiangsu Yueda Group

Known for its high-quality crankshaft production, Jiangsu Yueda Group has established itself as a leader in the automotive industry. They focus on innovation and have invested heavily in R&D.

2. Shanghai Shenda Group Co., Ltd.

With decades of experience, Shanghai Shenda specializes in producing crankshafts for both diesel and gasoline engines. Their commitment to quality ensures a long-lasting product.

3. Chongqing Pankow Technology Co., Ltd.

This company offers a wide range of crankshafts and has built a reputation for reliability and efficiency in its manufacturing processes, making it a preferred choice for many auto manufacturers.

Benefits of Sourcing Crankshafts from China

There are several advantages to sourcing crankshafts from Chinese manufacturers:

- Cost-Effectiveness: Competitive pricing without compromising on quality.

- Technological Advancement: Many manufacturers invest in the latest technology, resulting in superior product quality.

- Diverse Product Range: Options available for various engine types and specifications.

- Custom Manufacturing: Ability to meet specific design requirements as per client needs.

Quality Control Processes in Crankshaft Manufacturing

Quality is paramount in crankshaft manufacturing. Chinese manufacturers implement stringent quality control measures to ensure that each crankshaft is produced to the highest standards. Typical processes include:

1. Material Inspection

Raw materials are inspected to ensure they meet required specifications before production begins, guaranteeing the durability of the crankshaft.

2. In-Process Quality Checks

Throughout the manufacturing process, various checks are done to monitor precision and adherence to design specifications.

3. Final Testing

Before shipping, final tests are conducted to assess performance under simulated operational conditions.

Challenges Faced by Crankshaft Manufacturers in China

While the potential of crankshaft manufacturers in China is vast, there are challenges that need to be overcome:

1. Competition

The industry is competitive, with many manufacturers vying for market share, which can lead to price wars and compromises in quality.

2. Compliance with Global Standards

As manufacturers expand into international markets, they must comply with various regulations and standards, which can be complex.

3. Supply Chain Issues

Global events can affect the supply chain, leading to delays in production and delivery, impacting customer satisfaction.

Future Trends in Crankshaft Manufacturing

The future of crankshaft manufacturing in China looks promising with trends indicating further innovations:

- Increased Automation: Automation and robotics are likely to enhance production efficiency and accuracy.

- Green Manufacturing: There is a growing emphasis on environmentally friendly practices, reducing waste and energy consumption.

- Smart Manufacturing: The integration of IoT technology is expected to drive efficiencies in production and supply chain management.

How to Choose the Right Crankshaft Manufacturer

Choosing the right crankshaft manufacturer in China requires careful consideration. Here are some factors to evaluate:

- Experience: Look for manufacturers with a proven track record in the industry.

- Certifications: Ensure they meet international quality standards.

- Client Testimonials: Check reviews and feedback from previous customers to gauge reliability.

- After-Sales Support: Quality after-sales service is critical in addressing any issues that arise post-purchase.

Conclusion

In summary, crankshaft manufacturers in China are at the forefront of innovation and quality in the automotive industry. By understanding the importance of crankshafts, the manufacturing landscape, and the benefits of sourcing from China, businesses can make informed decisions that enhance their operations. With advancements in technology and a commitment to quality, Chinese manufacturers are set to remain a dominant force in the global market for automotive parts.

For businesses needing diesel engine parts or looking for reliable spare parts suppliers, working with established crankshaft manufacturers can lead to long-term success and operational efficiency. The insights provided in this article serve as a valuable resource for those looking to understand the intricate world of crankshaft manufacturing and its impact on the automotive industry.